Evil Wreckoning Test

Evil Bikes had a rough start with their initial production run. They learned from their mistakes and have since been making carbon bikes that are aggressive in nature with a suspension platform that is very efficient. The brand originated making the first Chain Guide that actually worked for Downhill racing. It was a small start but soon the brand found it chain retention system on a majority of bikes out there. This lead to them creating some DH and Street hard tail bikes that would eventually prove to become collectable and the thing of legend.

Evil as we know it today is owned by Kevin Walsh. He purchased the brand from Dave Weagle back in 2008. Since buying Evil they had some problems on the manufacturing side with their first few runs of the Downhill bikes. With manufacturing happening in big quantities it took things awhile to get sorted out. Once production issues where sorted the guys at Evil took care of customers that had problems. Their carbon trail and downhill bike have been very successful. Last year Evil made the jump into the short travel Wagon Wheel segment with a bike called The Following that by many testers standards was considered The Holy Grail. Shortly after the launched The Insurgent a 650b trail slay machine offering 151mm of rear travel. Now Evil has launched the 161mm travel 29" wheeled rock crusher called The Wreckoning! Evil bikes is now using the same factory as Santa Cruz bikes for the production of the full carbon Evil bikes and with SC's experience in building carbon bikes it sounds like a good choice.

Build Kit

- Evil Wreckoning XL

- DVO Diamond 160mm

- Enve DH Bars 800mm

- Hope 35mm Stem

- Chromag Grips

- Hope Tech 3 V4 Brakes 203mm F/R

- Rock Shox 170mm Dropper

- Fabric Carbon Saddle

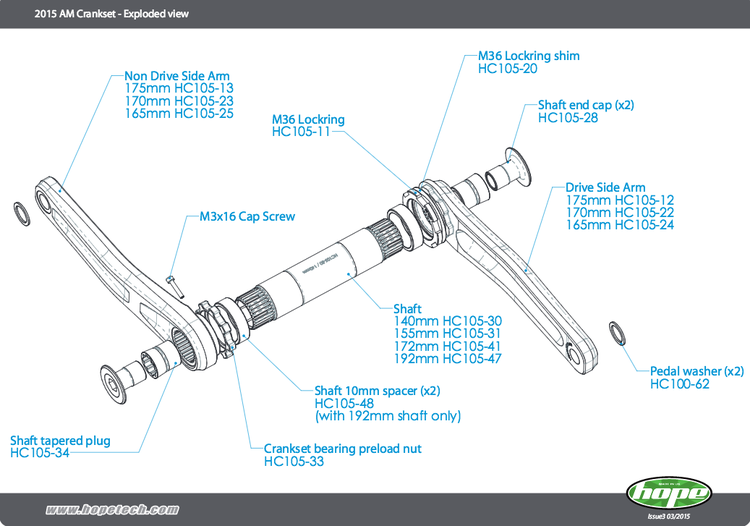

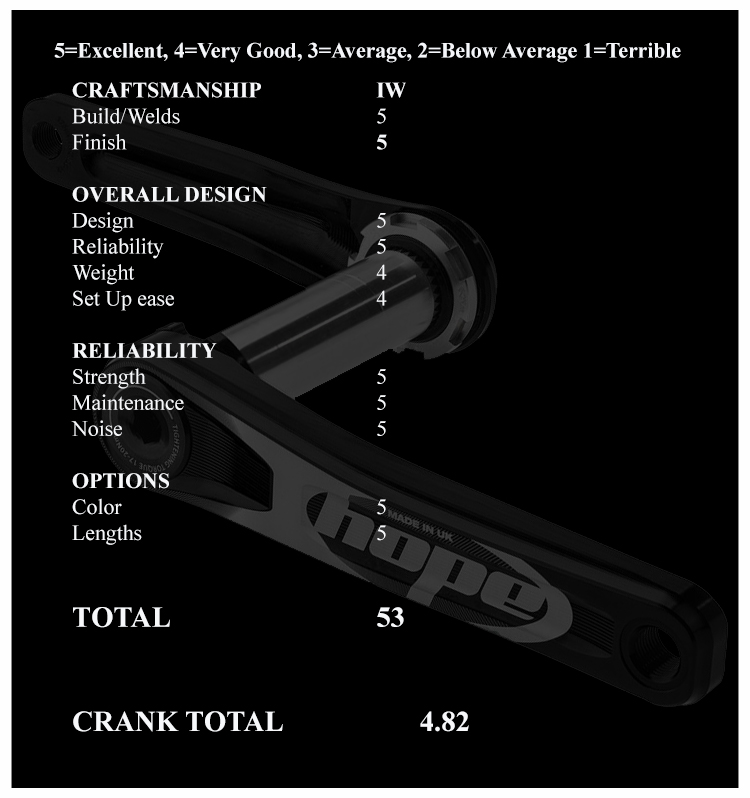

- Hope 170mm Cranks

- Hope 32 Tooth Chainring

- Gamut Podium Pedals

- SRAM XO Shifter

- SRAM XO 11 SPD Derailure

- SRAM XO 11 SPD Casette

- Industry Nine 29" Enduro Wheels

A FORCE TO BE RECKONED WITH

With the Following, Evil Bikes gave the world a taste of what a 29'er was capable of when developed by a small company whose agenda was to have fun on bikes. This was soon followed by the Insurgent, a 27.5” machine that is aimed more at the clientele that Evil originally became popular with - a crowd who won’t shy away from pedaling to the top of the mountain, but who really come alive on the way down. It would be trivial to say that the Wreckoning is the love child of these two bikes, because it is certainly more than that. The madmen over at Evil have once again scrutinized the boundaries of mountain biking today and decided they could simply roll right over them, on stiff new 29” wheels powered by Boost 148, and 161mm of DELTA suspension.

Features

- Wheel Size: 29"

- Frame Material: Carbon

- Rear Shock: Rock Shox Monarch RC3+ Debonair

- Rear Susp. Travel: 161mm

- Rear Shock Size: 216x63mm (8.5 x 2.5")

- Rear Axle Standard: 12x148mm Boost

- ISCG Tabs: Custom

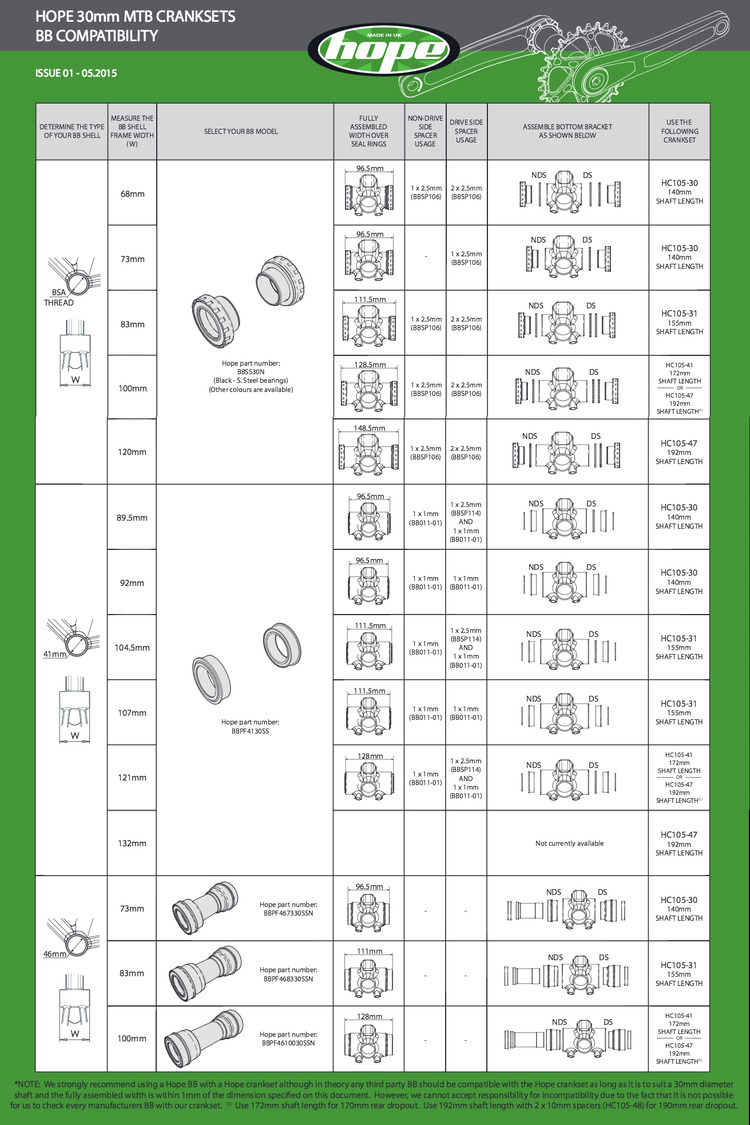

- BB Standard: 73mm BSA

- Seat Post Dia: 34.9mm

- Seat Clamp Dia: 39mm

- Headset Standard : ZS44/ZS62mm

- Intended Use: AM/Enduro/FR

- Warranty: 3 Years

Fanatik Bike's Take

"With the Following, Evil Bikes gave the world a taste of what a 29er was capable of when developed by a small company whose agenda was to have fun on bikes. This was soon followed by the Insurgent, a 27.5” machine that is aimed more at the clientele that Evil originally became popular with - a crowd who won’t shy away from pedaling to the top of the mountain, but who really come alive on the way down. It would be trivial to say that the Wreckoning is the love child of these two bikes, because it is certainly more than that. The madmen over at Evil have once again scrutinized the boundaries of mountain biking today and decided they could simply roll right over them, on stiff new 29” wheels powered by Boost 148, and 161mm of DELTA suspension.

Where other companies have been timidly approaching the sorts of numbers that many of us now feel make for the ultimate all mountain ride, Evil pounced on them. The Insurgent’s long top tube, reach, and wheelbase have translated almost exactly over to the Wreckoning, while minor tweaks have been made to accommodate taller riders. The seat tube angle has been steepened up to 74.8 degrees in the high setting (when running a 160mm fork) and 73.9 degrees in the low setting. This seat angle is in the same range that many of the most capable enduro style bikes sit, and quite a bit steeper than that of the Insurgent. It allows for taller riders to comfortably fit this bike without shifting their weight too far back. Which brings up a point of curiosity: where is the size small Wreckoning? Evil has determined that packing everything into a small-sized Wreckoning package would simply result in a bike that doesn’t ride how they intended. For smaller riders looking for a DELTA-equipped, root-eating shred rig, the Insurgent is still the way to go. For the average trail, the Wreckoning is most at home running a 160mm fork, but for those looking for a 29” downhill monster truck, this bike has been tested with forks running all the way up to 180mm. Be forewarned, going this route will push the Wreckoning into downhill bike territory. Granted, it can still be pedaled up the hill, but it will require a bit of extra effort.

Evil scored a homerun with Dave’s Extra Legitimate Travel Apparatus (D.E.L.T.A.), and it has been scaled/tuned up for the Wreckoning. This frame sports a 8.5”x2.5” (length x stroke) Monarch Plus RC3+ Debonair, versus the 7.875”x2.25” version found on the 10mm shorter travel Insurgent. For those heavy hitting riders out there, the Wreckoning is available with a Rock Shox Vivid Air RC2 for an added $225. While slightly heavier, the added plushness of this beefier shock is definitely welcome during a day of pounding brake bumps at your favorite lift-accessed bike park. If you are primarily pedaling to the top of the hill to enjoy the descent, the Monarch is more than enough shock. While we’ve found that we tend to leave the compression switch in the open position on D.E.L.T.A. equipped bikes, it can be nice to have for extended pushes up fire roads.

The newest crop of full suspension bikes from Evil Bikes are all built using a unidirectional carbon layup with a one-piece molded construction at one of the most reputable carbon bike factories in the world, VIP Composites. Stiffness and durability are backbones of Evil’s commitment to quality, and after riding the Insurgent for six months and putting the Wreckoning through it’s paces, we can attest to that. Having sold a record number of Followings and Insurgents, we can speak to the high standard of QC that these bikes adhere to. The single pivot frame design is intrinsically stiff, stable, and reliable, and we have had virtually no warranty issues with Evil’s other current models. We expect the same to be true with the Wreckoning.

In the past, bike companies have often struggled with frame stiffness on 29’ers. With the advent of Boost 148, it is now possible to make a 29” wheel that approximates the similar strength and stiffness to it’s smaller siblings. This bike does not compromise when it comes to straight line speed, and this is largely due to the roll-over capabilities of the large wheel paired with increased stiffness resulting from this new hub standard, the beefy single pivot swingarm, and carbon fiber construction. Other features carry over from the Insurgent, such as the integrated carbon chainguide, the built in sag indicator, a threaded BB, and the option to run Evil’s own custom E13 lower guide/bash guard.

The Wreckoning features internal cable routing for the dropper post, and external routing for the rear shifter and rear brake lines. The rear derailleur line is routed next to the brake line underneath the top tube, then internally through the seatstay.

The Wreckoning frame comes stock with a Rock Shox Monarch RC3+ Debonair rear shock (with the Vivid Air RC2 available as an upgrade), FSA sealed bearing headset, a Boost 148 (12x148mm) axle, and rubber downtube/chainstay/seatstay protectors. The frame is backed up by Evil's three year warranty. Evil bikes and frames may only be shipped within the United States."

The Delta Suspension System

"(Dave’s Extra Legitimate Travel Apparatus ) Despite Delta representing Dave Weagle’s 3rd cycling specific suspension system, we thought a super tech acronym would be much more appropriate. Well, if we had our way we would say it bends in the middle, stops and goes. But let’s be realistic, we can’t get away with that simple of an explanation. As much as we would like to think that everyone will have the opportunity to test ride an Evil, the reality is most of You will buy based on reviews, friends or Weagle’s past successes.

So the following is straight from the horses mouth ( Dave Weagle being the horse ). The DELTA system was conceived to, among other things, achieve very complex leverage rate curves that can be used to tune for varying track conditions, spring, and damper parameters. The dual progressive leverage rate curve was developed for coil sprung downhill applications to take advantage of the speed sensitive shocks on the market. Mechanically, the system uses very compact links that can achieve a lot of angle and velocity change through the travel. We can tailor the leverage rate curve to really take advantage of the shock’s valving and the way that a speed sensitive damper is designed to work. Ultimately the design achieves a high degree of suppleness early in the travel, with a very predictable high traction stage through the middle and a bottomless ramp at the end of the travel.

The whole suspension system, every attribute, is developed concurrently with each other, with the shock absorber, and with the bike’s intended use and geometry in mind. Main pivot location was carefully chosen to give the best balance of acceleration and braking performance. This careful positioning lets the bike accelerate without the need for excess damping, which in turn helps us push the limits of shock setup as far as possible to achieve ideal damper setup for any World Cup track. One of the biggest advantages of the system is its ability to let riders and mechanics adjust frame geometry without changing leverage rate and wheel rate at all.

Additionally, different link kits can be used to make drastic changes in the bike’s feel. These link kits are something that Evil’s World Cup athletes will take advantage of to fine tune for the drastically different race courses that they compete on over a race season. There is no bad option.It all comes down to personal preference. If you like to run air shocks and a position sensitive damper, we can develop that tune. If you like yourframe geometry low in the BB and slack in the head angle, or vice versa and anywhere in between, it’s covered. Upgradeability, tuneability, and personalization is what it’s all about, finding that combination that’s perfect for you and no one else."

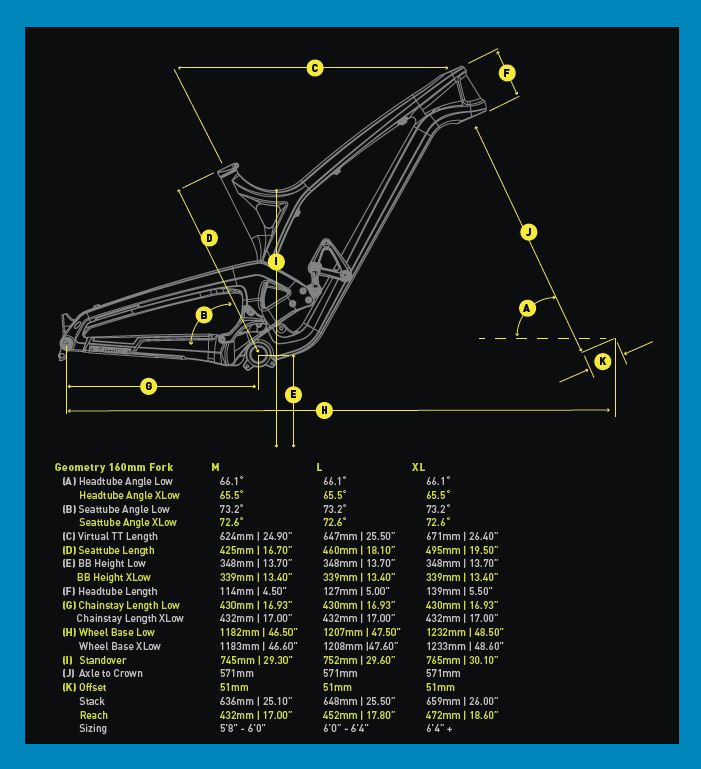

Looking at The Evil Wreckoning geometry numbers below it becomes apparent that they went for a slacker and somewhat longer frame than many companies making 29" Enduro bikes. The HA and BB numbers are adjustable via The Flip Chips. We opted to run the bike in the LOW setting most of the time. Running it in X-LOW (64.8 degrees HA) with a 35mm stem made climbing some of the steep stuff around here a bit challenging. Keep in mind we tested The Niner WFO and it has what many considered at its launch very aggressive numbers for a 29" bike with 150mm of travel. The Evil is very slack for a wagon wheel bike we ran it in the 66.1 HA setting and that proved more than capable for most trails. Some people are concerned about crank clearance, but it wasn't much of an issue for us and the 170mm cranks. Our frame was an XL and I am 6' 2" tall.

Evil Wreckoning Geometry

Evil Wreckoning Features

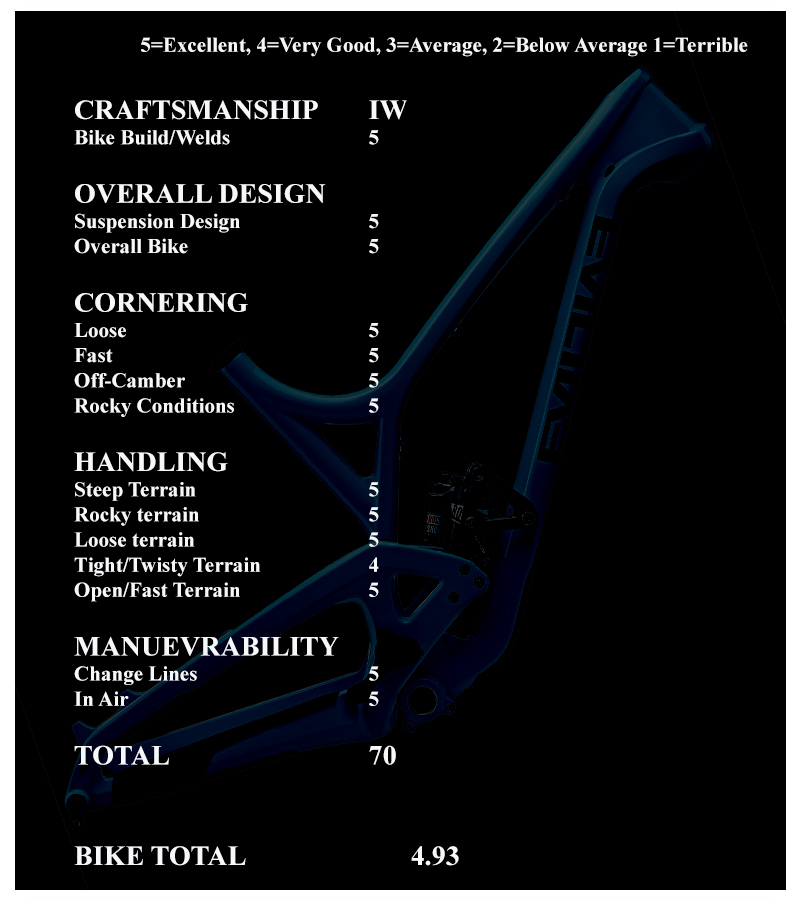

The Wreckoning proved to be a very capable Enduro/Trail Bike. It had the ability to climb well and descend chunky terrain at alarming rates of speed. It took a little while to get used to the bikes copious amounts of travel and what the larger wheels will allow you to mow over. The Wreckoning doesn't really feel fast per say, but it's times prove that it can be a KOM capturing machine if that is your thing! The bike offers gobs of traction, aggressive geometry, great suspension platform and wagon wheels.

The D.E.L.T.A. suspension is very supple at the very beginning of its travel. Once the bike's suspension seems to cycle well and offers traction by the boatload. Dave Weagel initially designed The Delta linkage for the Evil Undead and the high shaft speeds sometimes encountered during Downhill Racing. The Wreckoning offers two settings through the chips either Low or X-Low. The X-Low mode lengthens the WB, CS and also lowers the BB. For a majority of the test we ran The Wreckoning in the Low setting which gave us a 66.1 degree HA. This is plenty slack on a 29" bike for most applications. With this setting the bike had no issues wandering on the uphill.

Ian Wilkinson

Evil seems to have created a 29" bike that can be used on trails and also taken to the park and resorts when open. While The Wreckoning probably isn't going to win a Pro Downhill race on rock filled trails like Tahoe has but it can for sure handle some rough terrain. Although the bike has a bunch of traction it is also pretty nimble. We had no issues moving it around on the trail. It wasn't as poppy or easy to move as The Following but the extra 40mm of travel is a fair trade off in the grand scheme of things.

The D.E.L.T.A. suspension on The Evil Wreckoning is very supple to start. You can run it pretty firm and it will cycle into the travel without any noticeable drag. A coil shock on the bike would be even more impressive and from the sounds of it the Push 11-6 is a dream on the frame. With our Following we needed to add bands into the shock to make it more progressive to help prevent bottoming. This doesn't seem to be the case with The Wreckoning. So far we typically use about 75-80% of the travel and a fast run on most of the local trails. While testing The Evil Insurgent we also had to add in air volume spacers because we chose to run The Rock Shox Vivid Air on the frame.

The first trail I took The Wreckoning on was a 900 foot climb. Our build came in at 33lbs but it still climbs well and offers good traction over loose rock. We opted to use the Rock Shox Monarch Plus RC3+ Debonair on this long travel 29r to help get to the top of the hills. Having the ability to adjust the compression with a flip switch is nice but 3 options just is not enough. I would much rather have LSC, HSC and a lock out feature but it worked well. This trail has some rocks at the start and the suspension tracked well over the fast rocky sections. Then it changes into a turn filled smooth trail (flow) with a few small climbs. There are a few tight turns on this trail and The Wreckoning can get away with less front end weighing than smaller wheeled Enduro bikes to get around corners. My record time on this trail was set aboard The Following almost one year earlier. I eventually bested that time by almost 9 seconds with this longer travel bike and this trail is fairly smooth and almost 5 minutes in length.

Many people are huge fans of short chain stays The Wreckoning is not super short but close. It moves quick when you lean on the bars. I did notice that the big travel Evil had a wheelbase that was almost a full three inches longer than The Following we tested. This showed in fast, steep terrain add the extra travel and it can handle a much rougher trail. The Following and Insurgent where just not as stable and smooth on rowdier trails. The Wreckoning's rear suspension does feel almost bottomless. Riding it hard over rocky terrain you cannot tell when the shock is bottoming out which is very nice.

Above the previous trail is one that has close to 200 yards of rocks that range in size from golf ball to knee high. Faster riders can hit almost 20 mph going through this rough section. Typically I hover around the mid teens in this section. This is a good section to see how a bike tracks, rolls over terrain, eats square edge bumps and maintains its composure. The Wreckoning has a wheelbase that is 3 inches longer than The Following we tested last year. Both are 29' bikes but the travel, HA and WB differences become apparent when the trail becomes steeper and or rougher. Riding this trail on The Wreckoning showed how the extra travel and longer WB can help to smooth out a trail. It made the trail feel much smoother even when running over some bigger rocks while attempting hasty line changes at speed. The lower part of the trail is a bit more twisty but speeds increase here. Speed is what The Wreckoning is all about it just felt planted and wanted more. Riding the 29" wheels for sure gives a traction and roll over advantage compared to smaller wheels. The damn bikes just roll along faster as well and cover more ground. "Bigger wheels, bigger momentum- it is as simple as that. More momentum will allow you to roll through technical sections with a smaller chance of getting hung up on obstacles."

I commuted into work a number of time on The Wreckoning. This is a 25 mile ride on the pavement and a bit longer if you take the dirt once you hit the top of the freeway climb. The bike is big I am using heavy tires it weighed in at 33lbs completes in a size XL. With all those things considered it wasn't bad riding a longer pedal, spin fest aboard The Evil. The D.E.L.T.A. link does a good job at keeping bob in check. I ran the Rock Shox Monarch in firm mode to help even more. People have complained about the seat angle of the new Evil bikes and I would say this one gave me no issues at all and in fact was probably the better of the three that we have tested in that regard.

Conclusion

Overall we liked The Wreckoning. It has a great suspension system that works as DW designed it. The platform allows riders to put power down, climb, handle chunky terrain and provides good mid stroke support. The bike has a longish wheel base and slack head angle making it stable at speed. Combine that with a stiff frame and the wagon wheels and you have a great option for the more aggressive Enduro racer. We would not hesitate to recommend it to a friend looking for an aggressive Enduro bike or an All Mountain bike that could handle park trips fairly well.

Evil came at the long travel 29" market in a similar fashion as they did with the short travel 29" market. They created a slack, low, long bike with a suspension system that provides abundant traction, pedals well and essentially feels almost bottomless. Our Wreckoning was built to cater more to the gravity rider. Those looking for a more trail friendly version can easily shave 2 lbs off our build to keep it close to the 30lbs mark.

There are a few things Evil could do to improve The Wreckoning and both are small changes. The first would be to add a water bottle cage mount just above the shock. Again we had to fabricate our own sing a strap and rubber to hold a cage onto the frame. Next they should look at giving just a bit more tire clearance in the rear stays and while at it throw in some rubber protection to keep rocks from chipping the paint or carbon.

We have tested all three of Evil's trail bike offerings. If pressed to pick one it would probably be The Wreckoning or Following. There is a noticeable difference with the 29" wheels. Where we live is pretty rocky so roll over ability is huge. Wagon Wheeled bikes just roll faster and cover more ground. I would say The Wreckoning frame is stiffer than The Following was and this is in large part due to them using a beefed up chassis and possibly from using a Boost rear on the bike. All three of Evil's trail bikes are good. With The Wreckoning you have a 161mm, 65.5 HA 29" trail bike that can flatten some fairly rowdy terrain. It is pretty close to a do it all bike. Riders can do 40 mile excursions with it or take it to the bike park and it will do both without asking to much form you. Riders that are stuck on the short travel trip once faced with rockier and heavier load trails will soon find themselves have reliability issues with their lighter weight bikes. With The Wreckoning the rider can hammer some hard terrain and not have to worry so much about it developing stress fractures and the rear end of the bike packing up under high speeds over rough terrain.

29',

29',  All Mountain,

All Mountain,  DELTA,

DELTA,  DW,

DW,  EWS,

EWS,  Enduro,

Enduro,  Evil Bikes,

Evil Bikes,  Evil Wreckoning,

Evil Wreckoning,  Evil Wreckoning Review,

Evil Wreckoning Review,  Kill Trail,

Kill Trail,  Wagon WHeels,

Wagon WHeels,  Wreckoning Test |

Wreckoning Test |