2018 YT Capra Announced

Thursday, February 8, 2018 at 6:31AM

Thursday, February 8, 2018 at 6:31AM Confidence, creativity, endurance: this G.O.A.T. will get you and it will turn you into the rider you have always aspired to be. And true to our core we keep pushing boundaries: the all new CAPRA is a full-on downhill machine crossed with the uphill performance of a trail bike.

Bomb proof tracking, a finely tuned responsiveness and railroad track cornering: the CAPRA has reserves keen to handle downhill minefields with the brutal ease of a trophy truck. A bike that just begs to be pushed hard, the perfect tool to unlock those big, wild rides.

On the trail the CAPRA flies, carves and thrills all the way down, giving you the light-footed pop and playfulness of a fawn that sees it’s first spring. While on the uphill it resembles its name giver, the G.O.A.T., the confident, effortless and most skillful climber out there. The real king of the mountain - the greatest of all time.

27 or 29 – not an easy decision. Because both CAPRAs are dialled into a perfect combination of aggressiveness, speed, agility, and handling, there's no obvious 'right' answer. Your riding style, preferred terrain, and - last but not least, personal preference are the deciding factors.

The CAPRA 29 offers unbeatable control and stability on fast downhills while being an efficient climber on the uphills. Planted low between the axles you form a unity with the bike that offers instant confidence. Thanks to the slack headtube angle, the long wheel base and those tall, capable wheels the CAPRA is the perfect tool to conquer the Megavalanche while at the same time giving you pedalling efficiency over long distances with plenty of up- and downhills. The outstanding grip provides unheard-of propulsion on those gruelling climbs and thanks to the FlipChip the geometry can be perfectly adapted to your needs.

The CAPRA 27 is for all of those looking for the playful agility of an enduro bike combined with the gravity genes of a downhiller. The extra suspension travel ensures it doesn't give any ground when dealing with rough terrain or soaking up sketchy landings. The slack headtube angle and long wheel base ensure perfect traction while the extra short chainstays make the bikes insatiably fast and addictively engaging - on the ground and in the air. You will ride longer and crazier than ever - and will never need a lift again.

For the new generation of the CAPRA we have fine-tuned our much-acclaimed Virtual 4 Link suspension system even further. We adopt the downhill principle due to the low transmission and thus create the characteristics of V4L: an off-the-top sensitivity, even more ample mid-stroke support than before and a progressive ending stroke.

V4L not only gives you the confidence to hit big gaps and rugged terrain at speed, it also makes pedalling super-efficient. Additionally we have optimized the kinematics to further reduce the influence of pedalling forces. The result is an outstanding climbing efficiency with optimum climbing position and neutral riding behaviour - providing the perfect riding experience.

“The new CAPRA is just so f@#$%!* rad, you can really do EVERYTHING with it…It pretty sure can be as fast as on a downhill bike, so it’s my bike for every ride, every day. And the new bike geometry is gonna change the game of the enduro world. So let’s keep ripping trails and whipping through corners!”

Bryan Regnier

Our Frenchie definitely has the loosest style in the Enduro World Series and is a true fan favorite. As a foster son of Cedric Gracia, the former motocross racer knows how to combine good times and racing.

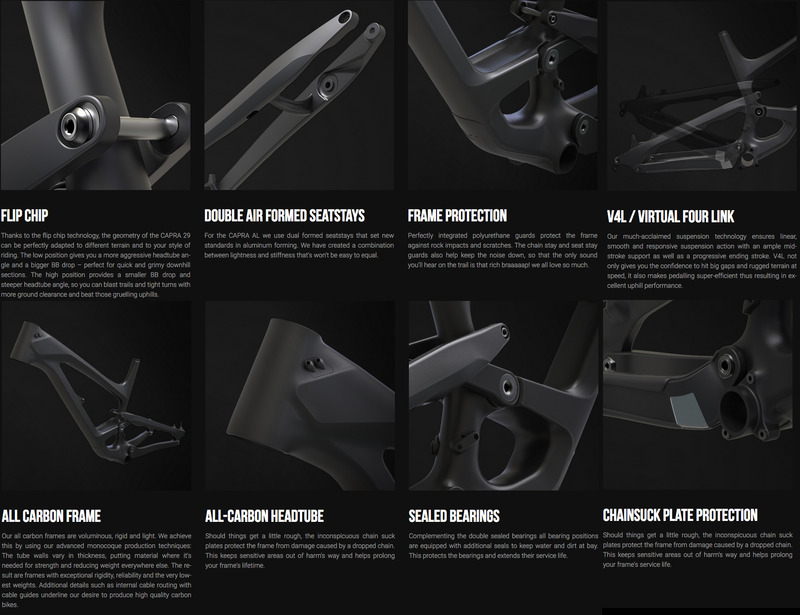

YT Capra Technology

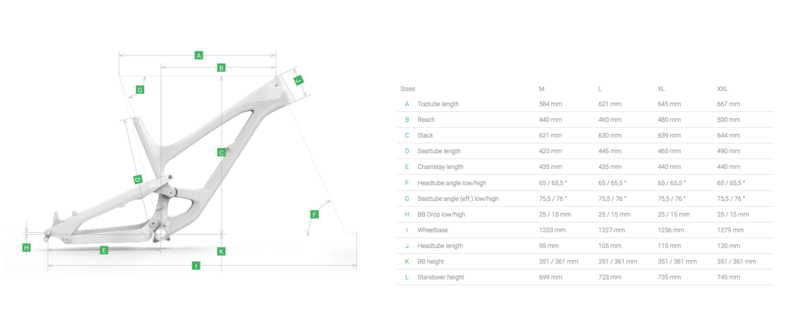

2018 Capra 29" Geometry

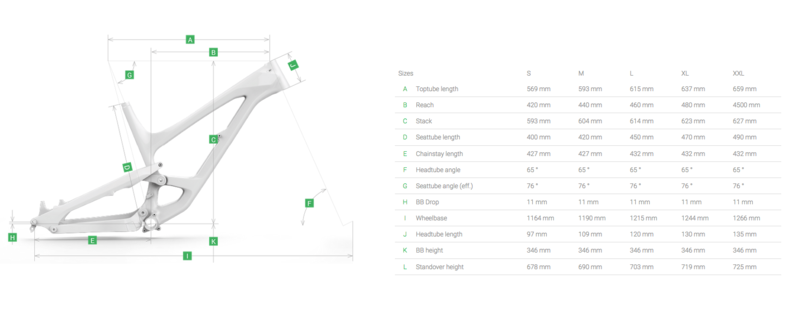

2018 YT Capra 27.5" Geometry

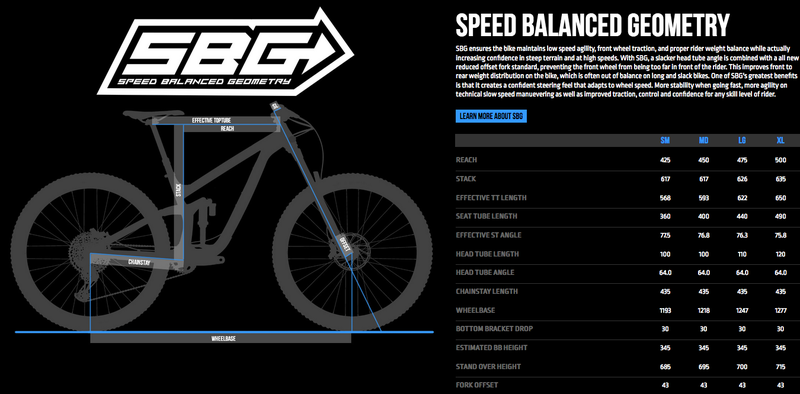

Our focus in the development process has always been to create the perfect weight distribution and optimum rider position. So for 2018, YT Tailor Made is taking things a step further.

Throughout all CAPRA bikes sizes we offer a low seatpost height in combination with seatposts, that are specifically matched to each of the bike sizes. Therefore riders can now choose between 2 to a maximum of 3 different frame sizes for their body height. Whether you prefer a moderate or long reach - you now have true freedom of choice. It's like your frame has been tailormade for you. By opting for the longer reach, experienced riders can adjust the weight distribution more precisely while the standard reach will give you a bike with a little more pop out of corners.

The seat angle of the new CAPRA is perfectly adjusted to a well-balanced pedaling position, allowing for maximum riding efficiency and pedaling prowess. The slack headtube angle and short chainstays, which again are adapted for each frame size, deliver the most advanced combination of trail bike agility and traction at downhill standard.

2018 YT Capra 27.5 CF ProCheck out the full build kits and color option on the YT Website.

2018 YT Capra 27.5 CF ProCheck out the full build kits and color option on the YT Website.

170mm,

170mm,  2018 YT Bikes,

2018 YT Bikes,  29" Capra,

29" Capra,  EWS,

EWS,  Enduro,

Enduro,  Wagon WHeels,

Wagon WHeels,  YT Capra |

YT Capra |