Hope AM/Freeride Stem Review

Monday, February 15, 2016 at 7:49PM

Monday, February 15, 2016 at 7:49PM  Permalink

Permalink

Hope Technology has been around for almost 40 years now. They began making their first disc brakes in the late 1980's. Over the years they have expanded their production to include hubs, stems, pedals, headsets, cranks, BB's, chainrings and a cassette is now in the works. They pride themselves with making all their parts in their home country of England.

Over the years we have owned many Hope products personally. Including Bulb and Big Un hubs, Mono 4, Moto V4 and and the newer Tech V4 brakes. All of their products worked well and their brakes in the past where nothing short of amazing. We decided to get a Hope AM Stem to test out on the "enduro" bike and see how this machined work of art performed going "full enduro".

"Hope Technology began life in the late 1980’s as a subcontract machining business making tools and fixtures for the many local aerospace companies. In 1989 they began making disc brakes for the newly developed mountain bikes. Initially for the personal use of the owners Ian Weatherill and Simon Sharp but they quickly realised these brakes could be sold as a product in their own right.

Since disc brakes were such a novel idea on a bicycle they decided to begin manufacturing other more common bicycle products, the first of these being a front hub. These began selling through retailers in the UK and interest was also shown in many countries around the world.

Over the subsequent years many more products were added to the range and in 2000 the decision was made to stop all subcontract work and concentrate purely on bicycle products.

Hope now manufactures almost every part for a bicycle including hubs, brakes, headset, stems, bottom brackets and lights. The only major part left to develop is the actual frame, which may be happening in the not too distant future. All parts are proudly manufactured in Hope’s Barnoldswick factory which is a true state of the art facility. They have almost 100 staff operating the factory 24-7, running the 55 CNC machines, anodising the individual components and hand assembling the finished parts. Manufacturing all products on site gives Hope total control on quality and delivery schedules.

Hope exports around 50% of its production to over 40 countries. They deal directly with retailers in the UK, France, Germany, Austria, Belgium and The Netherlands (employing French and German speaking staff), then have distributors in many other countries. Their components have an excellent international reputation for both quality and reliability. They are generally fitted by enthusiasts looking to upgrade their bikes to the highest levels and are supplied through specialist retailers."

Features

- CNC machined from 2014 T6 aluminium

- Designed for oversized 31.8mm bars

- Lengths- 35, 50 & 70mm

- Available in two rises - 0 or 20 degree ( 20 degree rise option only available with 50 & 70mm stems)

Specifications

- All stems are CNC machined from a solid billet of 2014 T6 aluminium

- The AM stem range has been redesigned with more material taken out to save weight and also features a new front plate design

- Opposing steerer clamp bolts remain to give exceptionally rigid steering characteristics

- Optimum machining to give lightest weight without compromising stiffness

- Available in: black, silver, red, blue, purple and orange

- Weight from: 134g

Opening the box we found a milled work of art from Hope. In their usual fashion the machine work was exemplary and the stem had a beautiful black anodizing. We got the 35mm stem and noticed right away that the front face plate was very wide. We mounted it up onto our Evil Insurgent and slid the Enve DH bars into the stem.

Everything went together easily. The hardware Hope uses is top notch and the threads on the bolts are very long. We used Park Tool Supergrip to make sure the carbon bars did not slip while we where riding. Having a high quality stem like this makes assembly easy and will add some extra bit of bling to your bike.

Riding the Hope Stem it never draws your attention. The last thing you want to be worried about is a bar or stem issue. Not once did the bar move or the stem make any sort of noise. During our five months of riding The Hope AM Stem we never once had any sort of issue.

Conclusion

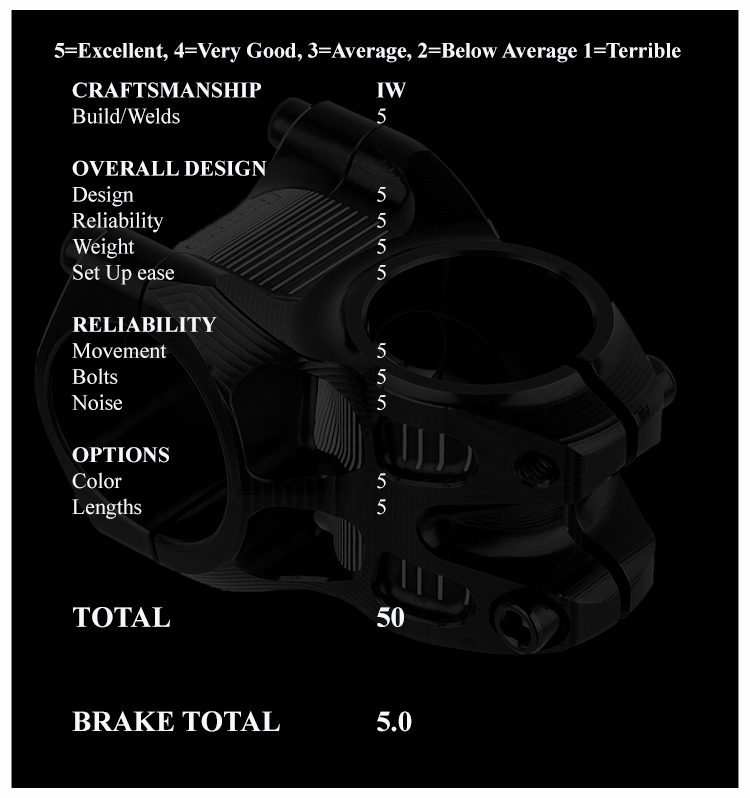

Overall we where very impressed by the level of craftsmanship of The Hope Am Stem. This comes as no suprise since every Hope product we have ever seen has been top notch. Selecting a stem comes down to length, color, bar diameter and rise. Hope offers the stem in numerous colors, lengths, and two rises. Currently they do not have a 35mm clamp option. It would make sense for them down the road to offer the larger diameter option.

We would for sure recommend The Hope Stem to a friend. It is a quality piece of kit that is made in England. They offer numerous options for riders to choose from. Sometimes the little guys just do it better. We would like to see a 35mm clamp diameter offered in the future.

Hope AM Stem,

Hope AM Stem,  Hope Freeride Stem,

Hope Freeride Stem,  Hope Stem,

Hope Stem,  Hope Stem Test,

Hope Stem Test,  Hope Technology |

Hope Technology |